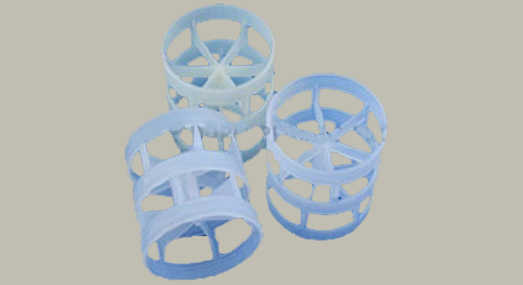

Plastic Pall Rings

Plastic Pall Rings

Plastic materials for the production of packings for towers have recently been used in many application fields in which formerly were restricted to metals and ceramic materials.

Selection of plastic materials depends on chemical resistance, temperature stability and mechanical strength. Polypropylene has good resistance to chemicals at temperatures up to more than 100 deg.C, polypropylene is superior to polyethylene in most fields.

The basic model consists of a cast iron casing and cast iron involute impellers. Carburized and ground alloy steel spur timing gears are secured to the steel shafts with a taper mounting and locknut. Oversized anti friction bearings are used, with a cylindrical roller bearing at the drive shaft to withstand V-belt pull. The features thrust control, with splash oil lube on the gear end and grease lube on the drive end. After standard tests, the unit is sprayed with a protective paint and boxed or placed on skids. Available accessories include driver, relief valve, inlet and discharge silencers, inlet filter, check valve, extended base, v-belt or flexible coupling and drive guards.

- » The basic property of Polypropylene PP - Density: 920kg/m3

- » Types used: Operational temperature range:

- » Polypropylene LTHA: up to +110 deg.C

- » Polypropylene alkali-proof: up to +110 deg.C

- » Cold-resistant : to -10 deg.C (depending on the type)

Resistant to acids like hydrochloric acid and sulfuric acid bases like caustic soda solution and causti- potash solution salt solutions like sodium chloride, ammonium chloride alcohols, ketones such as methanol, ethanol, acetone-organic acids like formic acid, acetic acid

No resistant to: strong oxidizing agents such as halogens like fluorine, chlorine, bromine halogenated hydrocarbons aromatic hydrocarbons

As to the resistance, the respective concentrations and temperatures are to be observed.

Technical Specifications

| Sizes mm | Surface m2/m3 | Free Vol.% | Number per m3 | Weight kg/ m3 |

|---|---|---|---|---|

| 37dia x 33mm lenght | 140 to 150 | 90 to 110 | 18,800nos | 75 |